We’ve seen this story play out many times: A customer orders replacement fuel injection parts, installs them, machine runs great for a few minutes or hours and then dies and won’t restart. They call us frustrated and tell us the product has failed and they need a replacement ASAP. We ask the customer to send us the failed product for analysis, we perform an evaluation, and many times determine the failure is related to Fuel Contamination.

Here are some common questions we receive regarding the subject of fuel contamination

So what is fuel contamination?

Fuel contamination is a broad term used to describe foreign materials (both liquids and solids) in the diesel fuel of a

machine. Some examples of fuel contaminants include but are not limited to: dirt, water, gasoline, DEF fluid, sand, salt,

metal from a previous failure, kerosine, solvents, emergency de-gel, alcohol and many more.

I’ve never had issues like this in the past, why am I having issues with contamination now?

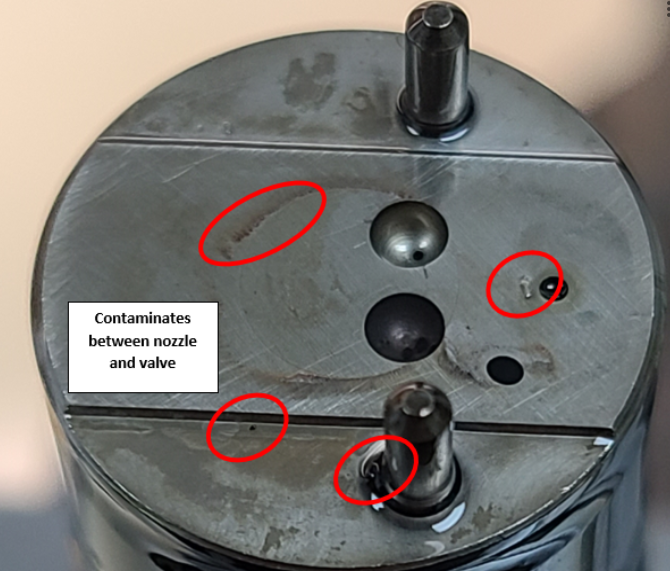

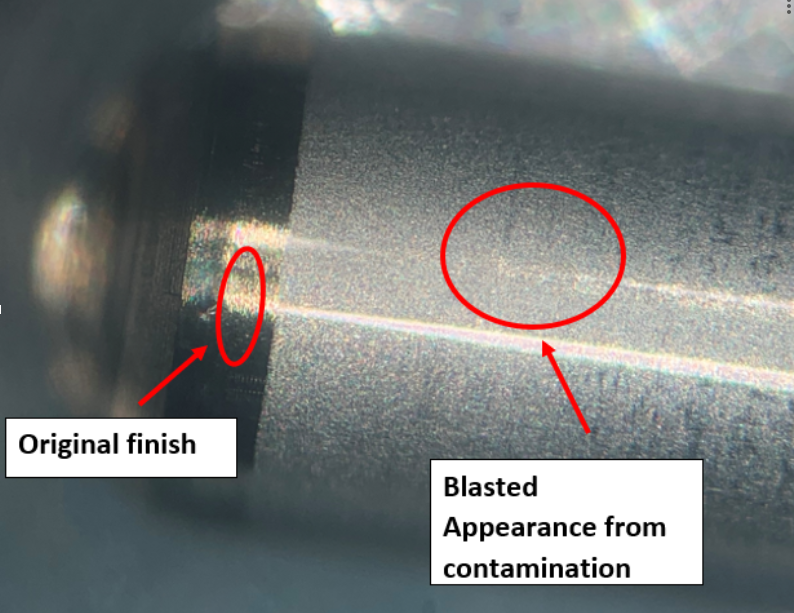

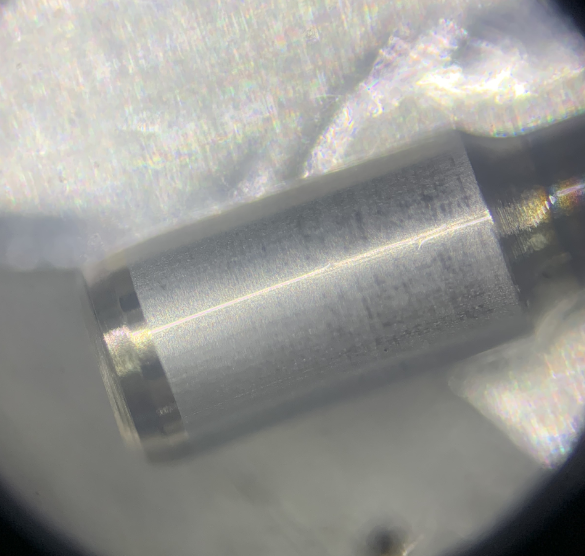

With the increased emissions standards came the advent of high pressure common rail fuel systems. These fuel systems are more vulnerable to damage from

contamination than previous injection systems due to tighter design tolerances. If small particles or debris are present in the fuel, the high pressure system effectively turns these debris into blasting media and severely score/rough up the critical surfaces of the injector to a point where the injector will no longer operate within specification

I cleaned out my entire system and replaced the fuel filter before replacing my injectors, pump, etc

Existing contamination has a lot of places to hide in a fuel system. If you replaced the Injectors, Fuel Pump, Fuel Rail,

and Fuel Filter, this is a good starting point. However, the contamination can sit in the return lines, the fuel tank, the fuel

cooler, the lines between the tank and the filter, the lines between the filter and the high pressure pump, the line from the

high pressure pump to the rail, the lines from the rail to the injectors, among other areas.

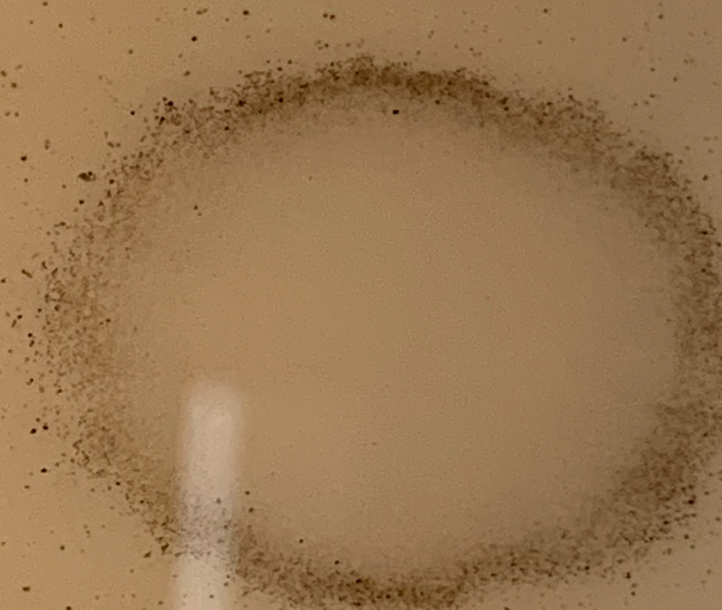

Another thing to think about is where your diesel fuel is coming from. Pictured above is a diesel can I saw while on vacation with my family in up-state Pennsylvania. I was curious and decided to take a look inside the can. What I saw was some algae and water mixed with off-road diesel. This can will eventually cause an expensive problem for the property owner and his small Kubota diesel tractor.

Before replacing failed fuel system components, identifying the root cause of your failure is most important. Otherwise, more money will be spent and additional downtime will result. Anything other than clean diesel fuel running through high pressure common rail systems will cause problems

Why don’t the manufacturer’s warrant this type of failure?

When a cell phone is dropped into a bucket of water while it’s powered on, it’ll, in most cases, cease to operate. The cell phone manufacturers have ways of identifying this water damage and deny warranty (assuming warranty doesn’t cover water damage). The failure of the phone has nothing to do with the materials used or how the phone was manufactured. The scenario is very similar to a failed injector due to fuel contamination. The fuel injector is not designed to ingest sand, water, metal, DEF, salt, kerosine, solvents, etc. Therefore, when these items are ingested (like a cell phone dropped in water), the injector will cease to function properly. This failure is not the fault of the materials used or the way it was manufactured. Since the major manufacturers only warrant their products against defect in material or workmanship, the claims related to contamination are denied.