Recently, Bobcat completely revamped the D18, D24, and D34 engines. As many of you are aware, the first generation of Doosan engines had its fair share of problems, specifically related to fuel system contamination. The second generation of doosan engines in Bobcat equipment include an all new Bosch Fuel System. This is great news for equipment owners. It’s important to note that we are fuel and air system specialists which is why we will focus on this part of the engine more than the others.

We will break the Bosch High Pressure Common Rail fuel system down into the following components:

- Fuel injectors

- Fuel Injection Pump

- High Pressure Fuel Rail

Fuel Injectors

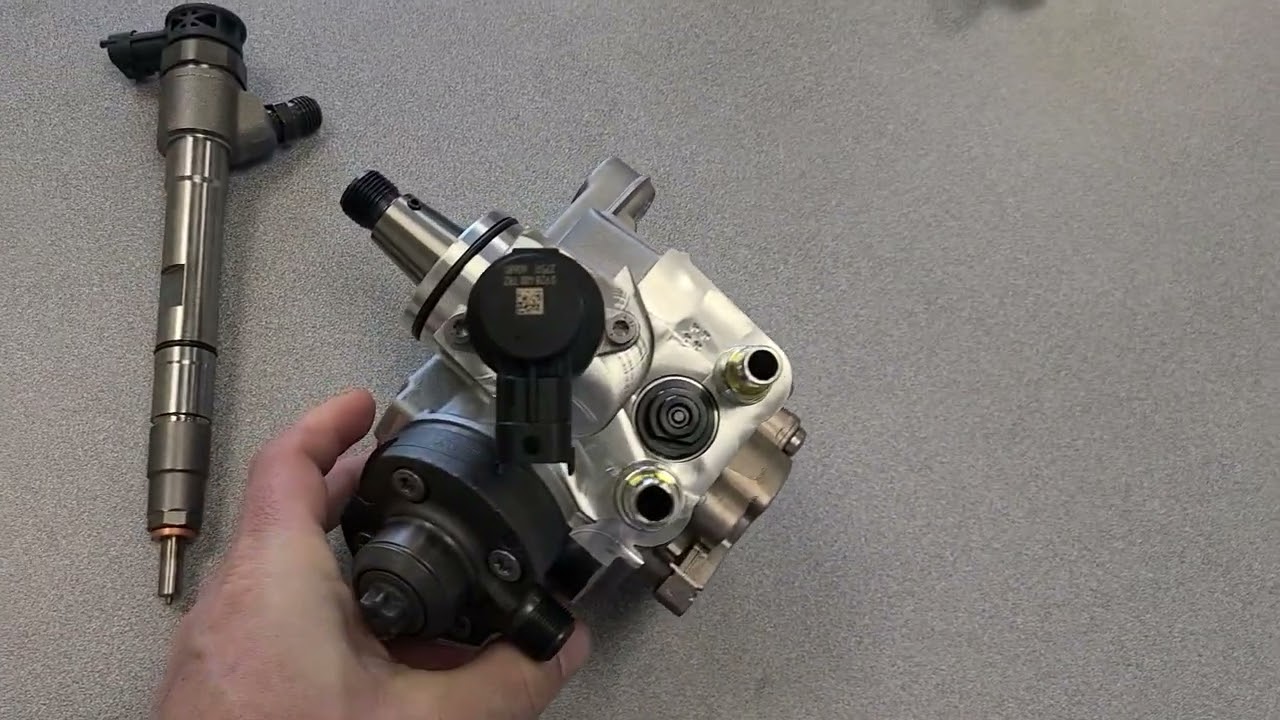

Beginning with the injectors, Bosch classifies these injectors as a CRI2-18 type. This injector type features an electronically controlled magnetic solenoid unit with a two pin connection, a traditional Bosch High Pressure Valve and nozzle which all work together to precisely control the fuel injection event. Bosch sends these injectors fully dressed including the o-ring on the body of the injector as well as a copper combustion chamber sealing washer. On the top of the solenoid, there is a unique trim code assigned to each injector. The programming of the trim code into the ECM of the machine is necessary for emissions purposes. This setup is tried and true from Bosch and should be a long lasting, very durable injector.

Fuel Injection Pump

The fuel injection Pump is a CP4 style pump and consists of a fuel metering valve, cam driven plunger and head assembly, rear mounted supply pump, and an overflow valve. The ECM takes data from the rail pressure sensor and cylinder contribution/ fuel injection data to set pumping output using a signal to the fuel metering valve (IMV or inlet metering valve). The pump includes the mounting o ring, a keyed shaft, and is relatively easy to install as no “timing” is necessary given this is a high pressure common rail system.

High Pressure Fuel Rail

The primary reason these pumps fail catastrophically (we believe) is a sudden drop in fuel supply pressure to the high pressure pump or air drawing in from the low pressure system and entering the pump. When this happens, it allows the tappet to turn and will eat up the pump camshaft and tappet very quickly.

The final component of the fuel system is the Bosch Fuel Rail. The type formula for the rail is CR/V4/10-23 S. The rail consists of a rail pressure sensor, pressure limiting valve (to protect the fuel system against sudden surges in rail pressure), one fuel inlet fitting, 3 or 4 discharge fittings (depending on number of cylinders), and a fuel return barb. We offer the rail pressure sensor and pressure limiting valve separately as well as the complete rail.

Video Review of the Fuel System