Customers are always asking for tips and tricks to extend the life of their diesel engine. While I would love to say there is a complex solution only highly advanced diesel technicians are aware of, this simply is not the case. There are several simple measures any diesel owner can take to add years/miles to the life of their engine with very little effort. I like to use the Pareto principle when describing many things in life. The Pareto principle, simply stated, says that 80% of results come from 20% of efforts. Maintenance of a diesel is the secret sauce to longevity. The 20% of effort which yields 80% of results.

Here are a few true and tested practices to help any diesel engine owner:

- Change your oil and oil filter every 5000 miles – Some will say you can get 10,000 miles with a good synthetic oil, however, for the cost of an oil change, it’s better to err on the side of caution. I run a synthetic motor oil in my diesel and still change it every 5000-6000 miles along with the filter to be safe.

- Change your fuel filter every other oil change – The fuel filter is your engine’s first line of defense against dirt and debris in the rest of the fuel system. Today’s fuel systems are higher pressure than ever and with the higher pressure comes tighter tolerances. Introducing dirt and debris into the fuel system will cause premature wear of the injection pump and injectors, which can cause a host of other problems.

- Stay away from performance products – Chips, FASS fuel pumps, and performance injectors are attractive to the performance market. These items have their place in the industry, however, if you are trying to keep your diesel alive for as long as possible, forgo the temptation to “upgrade” components on your diesel engine. Engineers from Ford, GM, Chrysler, CAT, Cummins, Detroit, International etc. are sharp guys. The original equipment has been tested for thousands of hours and tweaked to perfection. This doesn’t mean there are not ANY smart “performance” improvements. Just that original equipment and design is sound. Don’t fall into the marketing trap of the performance industry or take advice from “Joe” with no transport at all engaging on a forum from his Mom’s basement.

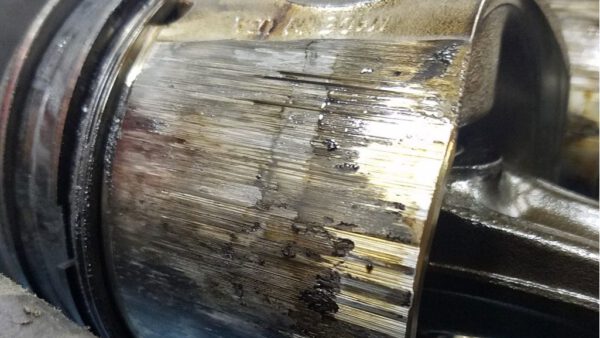

- Nip failures in the butt early – When you see the check engine light on , get the truck diagnosed as soon as possible. If you hear something funny, have a professional take a look. See an oil leak or fuel leak? Address these items when found. Small problems snowball into big problems. Letting problems snowball is a great way to ruin the engine prematurely. For example, you are checking your oil level regularly and you realize the engine oil level is increasing. OPTION A: You take your precious vehicle to the repair shop “X” who determines the engine was adding fuel to the oil. An injector seal had sprung a leak and started adding fuel to the crankcase. You replace the seal, change the oil, and your diesel engine is back on track to a long life. OPTION B: You ignore this problem and continue to run the engine until it shuts off. The fuel ruins the oil’s ability to lubricate the engine. All the bottom end components and pistons/sleeves rub against each other with no lubrication and the engine loses compression. Engine main bearings are shot. The engine will need to be replaced.