We get a lot of calls from our customers asking about the various components on the Bobcat common rail fuel injection systems. One of the most common problems we hear about is equipment where fuel has been contaminated and contamination has moved to the fuel injection pump, the fuel rail, and the fuel injectors. Here are a few tips to help you get your Bobcat equipment up and working the way it should be.

The Injection Pump:

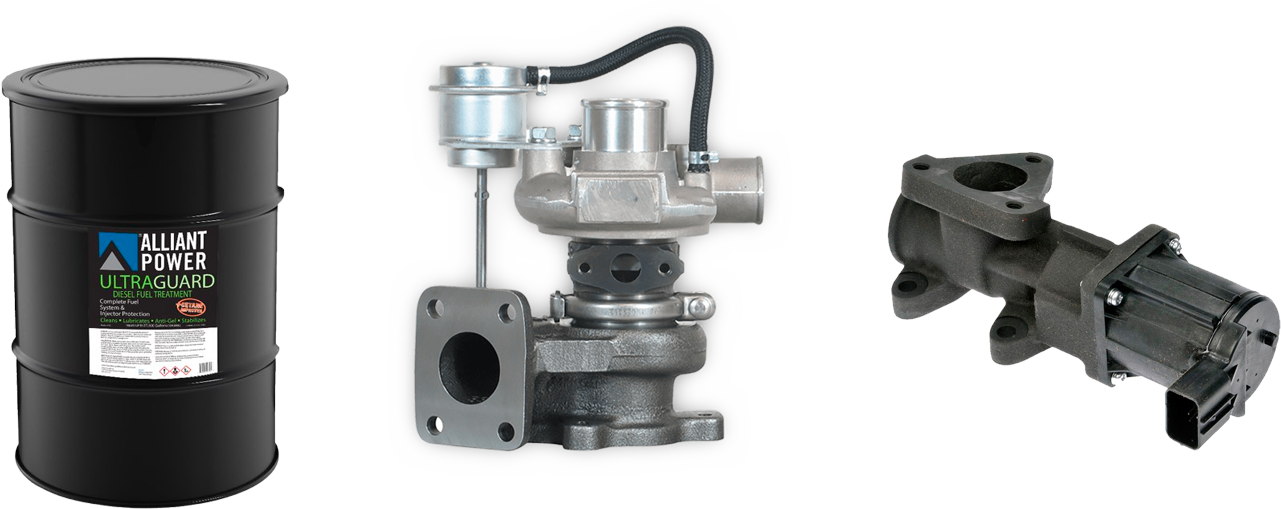

The Bobcat D24 and D34 injection pump for these engines is extremely sensitive to fuel contamination. If the injection pump is failing or has failed, the engine may not start or run but with low power.

A quick check you can do with the injection pump is to connect a scanner to the equipment and monitor desired vs actual rail pressure. If the injection pump is failing, the pump will have a difficult time keeping up with desired engine rail pressure.

Diesel Pro can test your injection pump. If you are interested in having your pump tested, give us a call.

D24 Pump: 7249380 Injection Pump

Inlet Metering Valve:

We get asked frequently about whether the inlet metering valve can be checked on the equipment. The inlet metering valve is responsible for metering rail pressure on the Bobcat D24 and D34 diesel engine. If the valve fails, the engine has no way of responding to commands to move rail pressure up or down.

One quick check you can do with the Inlet metering valve (IMV) is to put your finger on the valve and turn the key on in the equipment. You should feel a small vibration when the IMV is energized. If you do not, your IMV may be bad or wiring to the IMV may be compromised.

Fuel Injectors:

The Fuel injectors for the Bobcat Doosan D24 and D34 engines are high pressure common rail by Delphi. The most common reason for failure we see in these injectors is fuel contamination. The fuel control valves in these injectors are very small and any amount of debris in the injector can get lodged in the control valve and cause problems.

As we spoke about the injection pump and rail pressure earlier, the fuel injectors can also bleed rail pressure. With a scanner, you can monitor desired vs actual rail pressure to check and see if the engine has adequate rail pressure. The injectors will bleed rail pressure through the fuel return or could even have a nozzle stuck open (less common). Bobcat equipment software has a test to check the injectors to see if the respond to a signal.

Diesel Pro has developed an 8-step testing procedure to electronically simulate the on-engine conditions on our test equipment. If you are interested in having us test your injectors, give us a call.

D18 & D24 Injectors: 7275454 FUEL INJECTOR

D34 Fuel Injector: 7261663 Bobcat Doosan D34 Fuel Injector

Fuel Rail:

When the fuel system becomes contaminated with metal or other debris, chances are this debris will settle into the fuel rail. Bobcat recommends replacing the fuel rail when customers have an issue with contamination. The reason for this is there is no great way of cleaning the fuel rail. If you replace the injection pump or injectors and do not replace the fuel rail, there is a chance the debris sitting in the rail from a previous failure will once again be introduced into the components which were just replaced and cause premature failure.

D24 Fuel Rail 7030409 FUEL RAIL

Summary:

- Fuel contamination is the leading cause of failure

- If you are experiencing rail pressure codes or problems, it is most likely an issue with your injection pump or injectors

- Keep the fill area on your equipment clean and free of debris

- Change the fuel filter regularly to keep your fuel as clean as possible

- Bobcat has released an upgraded Fuel Filter to help resolve contamination issues. Our Contamination kits include the upgraded filter

Applications:

- Excavators: E32, E35, E42, E45, E50, E55, E85

- Toolcat Machines: 5600, 5610

- Skid Steer Loaders: S450, S510, S530, S550, S570, S590, S595, S630, S650

- Track Loaders: T450, T550, T590, T595, T630, T650